Machine Vision and AI for Industrial Innovation

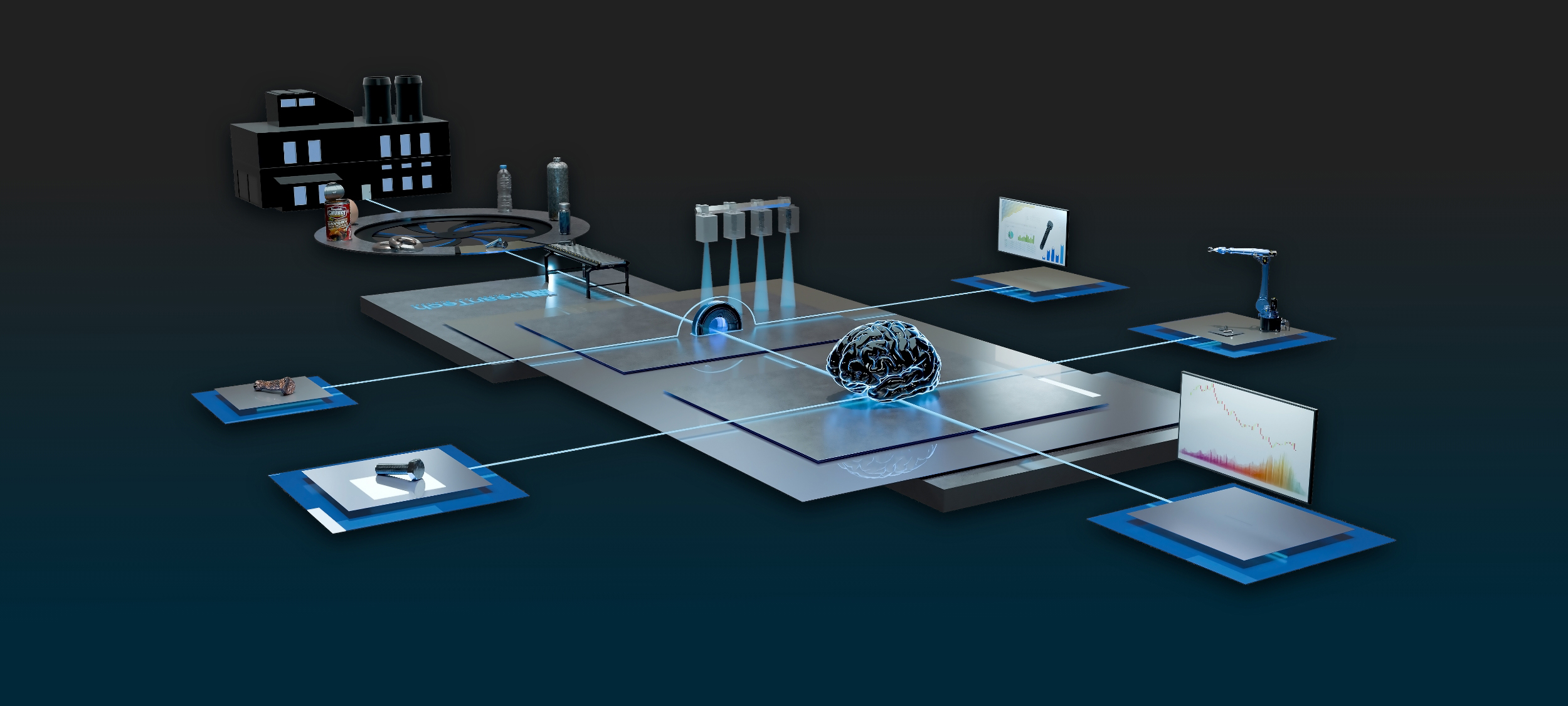

Ensure quality control, innovate your processes and improve production efficiency with solutions based on the integration of Automation, Machine Vision and Artificial Intelligence algorithms.

Our integrated Machine Vision and AI solution represents the cutting edge of quality control and process innovation for modern industry. By combining the power of machine vision with advanced AI algorithms, we are able to offer a unique and comprehensive approach to optimize production and ensure the highest quality products.

Through the synergy of cutting-edge Machine Vision technologies and AI systems, our solution enables real-time monitoring automation, minimizes defects, and consistently improves production processes while flexibly adapting to the specific needs of each industry.

This technological fusion not only increases operational efficiency, but also the competitiveness of companies, contributing to a smarter and more sustainable industrial future.

Machine Vision & AI: From Efficiency Improvement to Production Quality.

Discover all the benefits for your business!

Ensuring high quality standards and unprecedented productivity using Machine Vision systems?

We use only cutting-edge technologies for quality control and process innovation for the manufacturing world. Combining advanced Artificial Intelligence techniques with automated visual inspection and defect recognition, this solution not only ensures high quality standards but also revolutionizes manufacturing processes, taking efficiency and productivity to new levels.

Machine Vision and AI for manufacturing innovation: from food to pharmaceuticals, from steel industry to home appliance, to automotive. Here are some application cases:

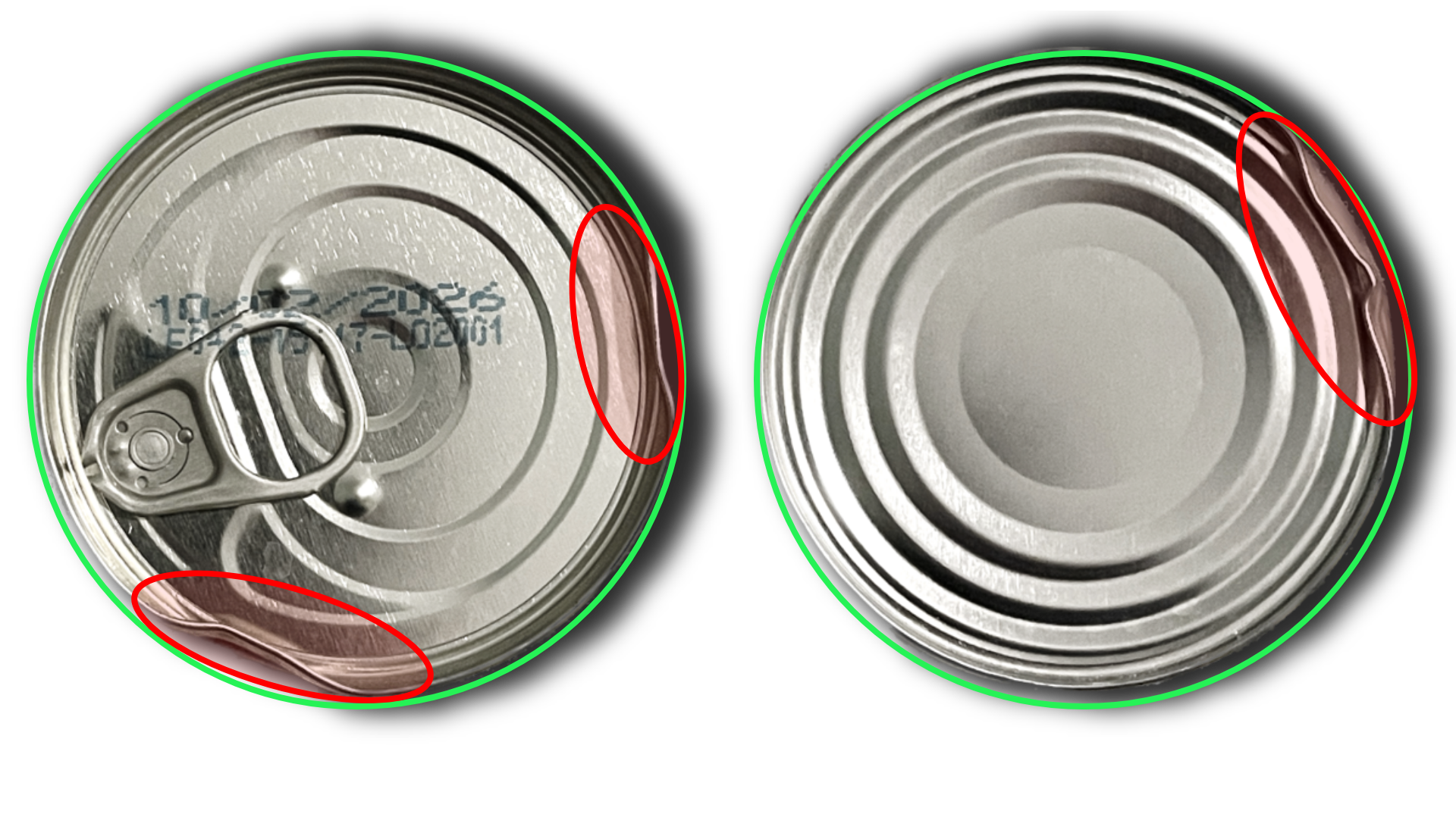

DEFECT REPORTING

Verification of product characteristics and any product anomalies that compromise product quality and end-customer satisfaction. Non-contact real-time quality control is followed by automation to eject unsuitable products without requiring any human intervention, reaching an accuracy of 99.99%.

PACKAGING

Checking the regularity of the packaging (presence/absence of scratches, cracks, dents), the conformity of the pre-packaged product and the packaging as a whole, identifying different parameters than those set and automatically identifying area, length and size of the defect compared to the theoretical parameter.

FINAL ASSEMBLY CONFORMITY

Through a smart-camera mounted on a cobot, a visual inspection is performed directly on the line, verifying that the assembly contains all the parts necessary for product compliance. The solution, together with the presence of the human operator, leads to close to 100 percent accuracy.

COUNTING AND SEPARATION

The solution, through a camera at the edge of the line, verifies that the filling of the contents inside a package conforms to the preset quantities. If it detects a shortage or surplus, it reports the error so that the operator can remove the failed piece from the line.

SHAPE, SURFACE AND FILLING

Verification of surface macro aspects that impact the final quality of the product (such as e.g., presence and/or absence of burn marks), the shape of the product and its perimeter (the product must not protrude from the package before packaging), and the filling, which must be consistent with “preset recipes.”

FILLING CHECK

Through a camera at the edge of the line, it verifies that filling of the contents inside a package conforms to the preset quantities. If a shortage or surplus is detected, it reports the error to the operator so that the operator can remove the failed piece from the line.

ON-LINE CONTROL

Real-time monitoring, using advanced AI algorithms, production at different process stages. This has made it possible to meet the highest quality standards and has brought numerous benefits: accurate objective control, improved automation, real-time process diagnosis, etc.

Is your company ready for the leap forward with Machine Vision & AI technologies? Find out if our solution is right for you:

Do you have mass productions and find defects in the finished product, despite any visual inspection by an operator?

Would you like to automatically monitor the quality of manufactured parts in real time and evaluate them through dimensional and surface quality checks?

Would you like to implement online feedback to manage nonconformities in real time?

Do you intend to implement a solution that cross-references process data with visual inspection to obtain prescriptive guidance and ensure production quality?

They couldn't help themselves...

Many leading manufacturing companies have chosen our Machine Vision and AI solution to refine quality control and innovate their production processes.

Reducing defects and increasing production efficiency have been possible through the use of innovative technologies such as advanced automation and process data integration.

Discover the results by reading some of our success stories!

Experience, innovation and attention to each customer's needs.

At beanTech, we develop tailored Machine Vision and AI solutions, accompanying companies at every stage of digital transformation. Our goal is to improve quality and optimize production processes, integrating advanced technologies to ensure concrete and measurable results.

Choosing beanTech means relying on a partner that combines technical expertise with a deep understanding of industrial challenges.

or you can call us at +39 0432 889787